Get Professional-Quality "Step-by-Step" Repair Instructions and Detailed Diagrams

Sulfuric acid (alternative spelling sulphuric acid) is a highly corrosive strong mineral acid with the molecular formula H2SO4. It is a colorless to slightly yellow viscous liquid which is soluble in water at all concentrations.Sometimes, it may be dark brown as dyed during industrial production process in order to alert people to its hazards.The historical name of this acid is oil of vitriol.

It is a diprotic acid which may show different properties depending upon its concentration. Its corrosiveness on metals, stones, skin, eyes and flesh or other materials can be mainly ascribed to its strong acidic nature and, if concentrated, strong dehydrating and oxidizing properties. Concentrated sulfuric acid can cause very serious damage upon contact as not only does it hydrolyze proteins and lipids leading to chemical burn, but also dehydrates carbohydrates resulting in secondary thermal burn. If it contacts eyes, permanent blindness may occur.So, safety precautions should always be taken when using it. Moreover, it is hygroscopic, readily absorbing water vapour from the air.

It is a diprotic acid which may show different properties depending upon its concentration. Its corrosiveness on metals, stones, skin, eyes and flesh or other materials can be mainly ascribed to its strong acidic nature and, if concentrated, strong dehydrating and oxidizing properties. Concentrated sulfuric acid can cause very serious damage upon contact as not only does it hydrolyze proteins and lipids leading to chemical burn, but also dehydrates carbohydrates resulting in secondary thermal burn. If it contacts eyes, permanent blindness may occur.So, safety precautions should always be taken when using it. Moreover, it is hygroscopic, readily absorbing water vapour from the air.

Possessing different chemical properties, the sulfuric acid has a wide range of applications including domestic acidic drain cleaner,electrolyte inlead-acid batteries and various cleaning agents. It is also a central substance in the chemical industry. Principal uses include mineral processing,fertilizer manufacturing, oil refining, waste water processing, and chemical synthesis. It is widely produced with different methods, such as contact process, wet sulfuric acid process and some other methods.

History

The study of vitriol began in ancient times. Sumerians had a list of types of vitriol that they classified according to substance's color. Some of the earliest discussions on the origin and properties of vitriol are in the works of the Greek physician Dioscorides(first century AD) and the Roman naturalist Pliny the Elder (23–79 AD).

Galen also discussed its medical use. Metallurgical uses for vitriolic substances were recorded in the Hellenistic alchemical works of Zosimos of Panopolis, in the treatise Phisica et Mystica, and theLeyden papyrus X.

Islamic alchemists Jābir ibn Hayyān(c. 721 – c. 815 AD), Razi (865 – 925 AD), and Jamal Din al-Watwat(d. 1318, wrote the book Mabāhij al-fikar wa-manāhij al-'ibar), included vitriol in their mineral classification lists. Ibn Sina focused on its medical uses and different varieties of vitriol.

Sulfuric acid was called "oil of vitriol" by medieval European alchemists. There are references to it in the works of Vincent of Beauvais and in the Compositum de Compositis ascribed to Albertus Magnus. A passage from Pseudo-Geber´sSumma Perfectionis was long considered to be the first recipe for sulfuric acid, but this was a misinterpretation.

Sulfuric acid was called "oil of vitriol" by medieval European alchemists. There are references to it in the works of Vincent of Beauvais and in the Compositum de Compositis ascribed to Albertus Magnus. A passage from Pseudo-Geber´sSumma Perfectionis was long considered to be the first recipe for sulfuric acid, but this was a misinterpretation.

In the 17th century, the German-Dutch chemist Johann Glauber prepared sulfuric acid by burning sulfur together with saltpeter (potassium nitrate, KNO3), in the presence of steam. As saltpeter decomposes, it oxidizes the sulfur toSO3, which combines with water to produce sulfuric acid. In 1736, Joshua Ward, a London pharmacist, used this method to begin the first large-scale production of sulfuric acid.

In 1746 in Birmingham, John Roebuck adapted this method to produce sulfuric acid in lead-lined chambers, which were stronger, less expensive, and could be made larger than the previously used glass containers. This lead chamber process allowed the effective industrialization of sulfuric acid production. After several refinements, this method, called the "lead chamber process" or "chamber process", remained the standard for sulfuric acid production for almost two centuries.

Sulfuric acid created by John Roebuck's process approached a 65% concentration. Later refinements to the lead chamber process by French chemist Joseph Louis Gay-Lussac and British chemist John Glover improved concentration to 78%. However, the manufacture of some dyes and other chemical processes require a more concentrated product. Throughout the 18th century, this could only be made by dry distilling minerals in a technique similar to the original alchemical processes. Pyrite (iron disulfide, FeS2) was heated in air to yield iron(II) sulfate, FeSO4, which was oxidized by further heating in air to form iron(III) sulfate, Fe2(SO4)3, which, when heated to 480 °C, decomposed toiron(III) oxide and sulfur trioxide, which could be passed through water to yield sulfuric acid in any concentration. However, the expense of this process prevented the large-scale use of concentrated sulfuric acid.

In 1831, British vinegar merchant Peregrine Phillips patented the contact process, which was a far more economical process for producing sulfur trioxide and concentrated sulfuric acid. Today, nearly all of the world's sulfuric acid is produced using this method.

Physical properties

Grades of sulfuric acid

Although nearly 99% sulfuric acid can be made, this loses SO3 at the boiling point to produce 98.3% acid. The 98% grade is more stable in storage, and is the usual form of what is described as "concentrated sulfuric acid." Other concentrations are used for different purposes. Some common concentrations are:

| Mass fraction H2SO4 | Density (kg/L) | Concentration (mol/L) | Common name |

|---|---|---|---|

| 10% | 1.07 | ~1 | dilute sulfuric acid |

| 29–32% | 1.25–1.28 | 4.2–5 | battery acid (used in lead–acid batteries) |

| 62–70% | 1.52–1.60 | 9.6–11.5 | chamber acid fertilizer acid |

| 78–80% | 1.70–1.73 | 13.5–14 | tower acid Glover acid |

| 98% | 1.83 | ~18 | concentrated sulfuric acid |

"Chamber acid" and "tower acid" were the two concentrations of sulfuric acid produced by the lead chamber process, chamber acid being the acid produced in lead chamber itself (<70% to avoid contamination with nitrosylsulfuric acid) and tower acid being the acid recovered from the bottom of the Glover tower.They are now obsolete as commercial concentrations of sulfuric acid, although they may be prepared in the laboratory from concentrated sulfuric acid if needed. In particular, "10M" sulfuric acid (the modern equivalent of chamber acid, used in many titrations) is prepared by slowly adding 98% sulfuric acid to an equal volume of water, with good stirring: the temperature of the mixture can rise to 80 °C (176 °F) or higher.

Sulfuric acid reacts with its anhydride, SO3, to form H2S2O7, called pyrosulfuric acid, fuming sulfuric acid, Disulfuric acid or oleum or, less commonly,Nordhausen acid. Concentrations of oleum are either expressed in terms of %SO3 (called % oleum) or as % H2SO4 (the amount made if H2O were added); common concentrations are 40% oleum (109% H2SO4) and 65% oleum (114.6% H2SO4). Pure H2S2O7 is a solid with melting point 36 °C.

Pure sulfuric acid is a viscous clear liquid, like oil, and this explains the old name of the acid ('oil of vitriol').

Commercial sulfuric acid is sold in several different purity grades. Technical grade H2SO4 is impure and often colored, but is suitable for making fertilizer. Pure grades such as United States Pharmacopeia (USP) grade are used for making pharmaceuticals and dyestuffs. Analytical grades are also available.

Polarity and conductivity

Anhydrous H2SO4 is a very polar liquid, having a dielectric constant of around 100. It has a high electrical conductivity, caused by dissociation through protonating itself, a process known as autoprotolysis.

- 2 H2SO4

H3SO+

H3SO+

4 + HSO−

4

The equilibrium constant for the autoprotolysis is

- Kap(25 °C)= [H3SO+

4][HSO−

4] = 2.7×10−4.

The comparable equilibrium constant for water, Kw is 10−14, a factor of 1010 (10 billion) smaller.

In spite of the viscosity of the acid, the effective conductivities of the H3SO+

4 andHSO−

4 ions are high due to an intra-molecular proton-switch mechanism (analogous to the Grotthuss mechanism in water), making sulfuric acid a good conductor. It is also an excellent solvent for many reactions.

4 andHSO−

4 ions are high due to an intra-molecular proton-switch mechanism (analogous to the Grotthuss mechanism in water), making sulfuric acid a good conductor. It is also an excellent solvent for many reactions.

The equilibrium is actually more complex than shown above; 100% H2SO4contains the following species at equilibrium (figures shown as millimoles per kilogram of solvent):

HSO−

4 (15.0), H3SO+

4 (11.3), H3O+ (8.0), HS2O−

7 (4.4), H2S2O7 (3.6), H2O(0.1).

4 (15.0), H3SO+

4 (11.3), H3O+ (8.0), HS2O−

7 (4.4), H2S2O7 (3.6), H2O(0.1).

Chemical properties

Reaction with water and dehydrating property

The hydration reaction of sulfuric acid is highly exothermic. One should always add the acid to the water rather than the water to the acid. Because the reaction is in an equilibrium that favors the rapid protonation of water, addition of acid to the water ensures that the acid is the limiting reagent. This reaction is best thought of as the formation ofhydronium ions:

- H2SO4 + H2O → H3O+ + HSO4− K1 = 2.4×106 (strong acid)

- HSO−

4 + H2O → H3O+ + SO2−

4 K2 = 1.0×10−2

HSO4- is the bi sulfate anion and SO42- is the sulfate anion. K1 and K2 are theacid dissociation constants.

Because the hydration of sulfuric acid is thermodynamic ally favorable and the affinity of it for water is sufficiently strong, sulfuric acid is an excellent dehydrating agent. Concentrated sulfuric acid has a very powerful dehydrating property, removing water (H2O) from other compounds including sugar and other carbohydrates and producing carbon, heat, steam, and a more dilute acid containing increased amounts of hydronium and bisulfate ions.

In laboratory, this is often demonstrated by mixing table sugar (sucrose) into sulfuric acid. The sugar changes from white to dark brown and then to black as carbon is formed. A rigid column of black, porous carbon will emerge as well.

- C12H22O11 (white sucrose) + sulfuric acid → 12 C(black graphitic foam) + 11 H2O (steam) + sulfuric acid/water mixture

Similarly, mixing starch into concentrated sulfuric acid will give elemental carbon and water as absorbed by the sulfuric acid (which becomes slightly diluted). The effect of this can be seen when concentrated sulfuric acid is spilled on paper which is composed of cellulose; the cellulose reacts to give a burnt appearance, the carbon appears much as soot would in a fire. The carbon will smell strongly of caramel due to the heat generated. Although less dramatic, the action of the acid on cotton, even in diluted form, will destroy the fabric.

- (C6H10O5)n + sulfuric acid → 6n C + 5n H2O

The reaction with copper(II) sulfate can also demonstrate the dehydration property of sulfuric acid. The blue crystal is changed into white powder as water is removed.

- CuSO4·5H2O (blue crystal) + sulfuric acid → CuSO4 (white powder) + 5 H2O

- As an acid, sulfuric acid reacts with most bases to give the corresponding sulfate. For example, the blue copper salt copper(II) sulfate, commonly used fo relectroplating and as a fungicide, is prepared by the reaction of copper(II) oxide with sulfuric acid:

Acid-base properties

- CuO (s) + H2SO4 (aq) → CuSO4 (aq) + H2O (l)

Sulfuric acid can also be used to displace weaker acids from their salts. Reaction with sodium acetate, for example, displaces acetic acid, CH3COOH, and forms sodium bisulfate:

- H2SO4 + CH3COONa → NaHSO4 + CH3COOH

Similarly, reacting sulfuric acid with potassium nitrate can be used to produce nitric acid and a precipitate of potassium bisulfate. When combined with nitric acid, sulfuric acid acts both as an acid and a dehydrating agent, forming the nitronium ion NO+

2, which is important in nitration reactions involving electrophilic aromatic substitution. This type of reaction, where protonation occurs on an oxygen atom, is important in many organic chemistry reactions, such asFischer esterification and dehydration of alcohols.

2, which is important in nitration reactions involving electrophilic aromatic substitution. This type of reaction, where protonation occurs on an oxygen atom, is important in many organic chemistry reactions, such asFischer esterification and dehydration of alcohols.

When allowed to react with super acids, sulfuric acid can act as a base and be protonated, forming the [H3SO4]+ ion. Salt of [H3SO4]+ have been prepared using the following reaction in liquid HF:

- ((CH3)3SiO)2SO2 + 3 HF + SbF5 → [H3SO4]+[SbF6]- + 2 (CH3)3SiF

The above reaction is thermodynamically favored due to the high bond enthalpy of the Si–F bond in the side product. Protonation using simply HF/SbF5, however, have met with failure, as pure sulfuric acid undergoes self-ionization to give [H3O]+ ions, which prevents the conversion of H2SO4 to [H3SO4]+ by the HF/SbF5 system:

- 2 H2SO4

[H3O]+ + [HS2O7]-

[H3O]+ + [HS2O7]- Reactions with metals and strong oxidizing property

Dilute sulfuric acid reacts with metals via a single displacement reaction as with other typical acids, producing hydrogen gas and salts (the metal sulfate). It attacks reactive metals (metals at positions above copper in the reactivity series) such as iron, aluminium, zinc, manganese, magnesium and nickel.

- Fe (s) + H2SO4 (aq) → H2 (g) + FeSO4 (aq)

However, concentrated sulfuric acid is a strong oxidizing agent and does not react with metals in the same way as other typical acids. Sulfur dioxide, water and SO42- ions are evolved instead of the hydrogen and salts.

- 2 H2SO4 + 2 e- → SO2 + 2 H2O + SO42-

It can oxidize non-active metals such as tin and copper, depending upon the temperature of it like the nitric acid.

- Cu + 2 H2SO4 → SO2 + 2 H2O + SO42- + Cu2+

Lead and tungsten, however, are resistant to sulfuric acid.

Reactions with non-metals

Hot concentrated sulfuric acid oxidizes non-metals such as carbon and sulfur.

- C + 2 H2SO4 → CO2 + 2 SO2 + 2 H2O

- S + 2 H2SO4 → 3 SO2 + 2 H2O

- Reaction with sodium chloride

It reacts with sodium chloride, and gives hydrogen chloride gas and sodium bisulfate:

- NaCl + H2SO4 → NaHSO4 + HCl

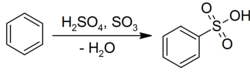

Electrophilic aromatic substitution

Benzene undergoes electrophilic aromatic substitution with sulfuric acid to give the corresponding sulfonic acids:

Pure sulfuric acid is not encountered naturally on Earth in anhydrous form, due to its great affinity for water. Dilute sulfuric acid is a constituent of acid rain, which is formed by atmospheric oxidation of sulfur dioxide in the presence of water– i.e., oxidation of sulfurous acid. Sulfur dioxide is the main byproduct produced when sulfur-containing fuels such as coal or oil are burned.

Sulfuric acid is formed naturally by the oxidation of sulfide minerals, such as iron sulfide. The resulting water can be highly acidic and is called acid mine drainage (AMD) or acid rock drainage (ARD). This acidic water is capable of dissolving metals present in sulfide ores, which results in brightly colored, toxic streams. The oxidation of pyrite (iron sulfide) by molecular oxygen produces iron(II), or Fe2+:

- 2 FeS2 (s) + 7 O2 + 2 H2O → 2 Fe2+ (aq) + 4 SO2−

4 (aq) + 4 H+

The Fe2+ can be further oxidized to Fe3+:

- 4 Fe2+ + O2 + 4 H+ → 4 Fe3+ + 2 H2O

The Fe3+ produced can be precipitated as the hydroxide or hydrous oxide:

- Fe3+ (aq) + 3 H2O → Fe(OH)3 (s) + 3 H+

The iron(III) ion ("ferric iron") can also oxidize pyrite:

- FeS2 (s) + 14 Fe3+ + 8 H2O → 15 Fe2+ (aq) + 2 SO2−

4 (aq) + 16 H+

When iron(III) oxidation of pyrite occurs, the process can become rapid. pHvalues below zero have been measured in ARD produced by this process.

ARD can also produce sulfuric acid at a slower rate, so that the acid neutralizing capacity (ANC) of the aquifer can neutralize the produced acid. In such cases, the total dissolved solids (TDS) concentration of the water can be increased from the dissolution of minerals from the acid-neutralization reaction with the minerals.

Sulfuric acid is used as a defence by certain marine species, for example, the phaeophyte alga Desmarestia munda (order Desmarestiales) concentrates sulfuric acid in cell vacuoles.

Extraterrestrial sulfuric acid

Venus

Sulfuric acid is produced in the upper atmosphere of Venus by the Sun's photo chemical action on carbon dioxide, sulfur dioxide, and water vapor.Ultraviolet photons of wavelengths less than 169 NM can photo-dissociate carbon dioxide into carbon monoxide and atomic oxygen. Atomic oxygen is highly reactive. When it reacts with sulfur dioxide, a trace component of the Venusian atmosphere, the result is sulfur tri oxide, which can combine with water vapor, another trace component of Venus's atmosphere, to yield sulfuric acid. In the upper, cooler portions of Venus's atmosphere, sulfuric acid exists as a liquid, and thick sulfuric acid clouds completely obscure the planet's surface when viewed from above. The main cloud layer extends from 45–70 km above the planet's surface, with thinner hazes extending as low as 30 km and as high as 90 km above the surface. The permanent Venusian clouds produce a concentrated acid rain, as the clouds in the atmosphere of Earth produce water rain.

The atmosphere exhibits a sulfuric acid cycle. As sulfuric acid rain droplets fall down through the hotter layers of the atmosphere's temperature gradient, they are heated up and release water vapor, becoming more and more concentrated. When they reach temperatures above 300 °C, sulfuric acid begins to decompose into sulfur trioxide and water, both in the gas phase. Sulfur trioxide is highly reactive and dissociates into sulfur dioxide and atomic oxygen, which oxidizes traces of carbon monoxide to form carbon dioxide. Sulfur dioxide and water vapor rise on convection currents from the mid-level atmospheric layers to higher altitudes, where they will be transformed again into sulfuric acid, and the cycle repeats.

Europa

Infrared spectra from NASA's Galileo mission show distinct absorptions on Jupiter's moon Europa that have been attributed to one or more sulfuric acid hydrates. Sulfuric acid in solution with water causes significant freezing-point depression of water's melting point, down to 210 K (−63 °C), and this would make more likely the existence of liquid solutions beneath Europa's icy crust.The interpretation of the spectra is somewhat controversial. Some planetary scientists prefer to assign the spectral features to the sulfate ion, perhaps as part of one or more minerals on Europa's surface.

Manufacture

Main articles: Contact process and Wet sulfuric acid process

Sulfuric acid is produced from sulfur, oxygen and water via the conventional contact process (DCDA) or the wet sulfuric acid process (WSA).

Contact process

Main article: Contact process

In the first step, sulfur is burned to produce sulfur dioxide.

- S (s) + O2 (g) → SO2 (g)

This is then oxidized to sulfur trioxide using oxygen in the presence of a vanadium(V) oxide catalyst. This reaction is reversible and the formation of the sulfur trioxide is exothermic.

- 2 SO2 (g) + O2 (g)

2 SO3 (g) (in presence of V2O5)

2 SO3 (g) (in presence of V2O5)

The sulfur trioxide is absorbed into 97–98% H2SO4 to form oleum (H2S2O7), also known as fuming sulfuric acid. The oleum is then diluted with water to form concentrated sulfuric acid.

- H2SO4 (l) + SO3 (g)→ H2S2O7 (l)

- H2S2O7 (l) + H2O (l) → 2 H2SO4 (l)

Note that directly dissolving SO3 in water is not practical due to the highly exothermic nature of the reaction between sulfur trioxide and water. The reaction forms a corrosive aerosol that is very difficult to separate, instead of a liquid.

- SO3 (g) + H2O (l) → H2SO4 (l)

Wet sulfuric acid process

Main article: Wet sulfuric acid process

In the first step, sulfur is burned to produce sulfur dioxide:

- S(s) + O2(g) → SO2(g)

or, alternatively, hydrogen sulfide (H2S) gas is incinerated to SO2 gas:

- 2 H2S + 3 O2 → 2 H2O + 2 SO2 (−518 kJ/mol)

This is then oxidized to sulfur trioxide using oxygen with vanadium(V) oxide as catalyst.

- 2 SO2 + O2 → 2 SO3 (−99 kJ/mol) (reaction is reversible)

The sulfur trioxide is hydrated into sulfuric acid H2SO4:

- SO3 + H2O → H2SO4(g) (−101 kJ/mol)

The last step is the condensation of the sulfuric acid to liquid 97–98% H2SO4:

- H2SO4(g) → H2SO4(l) (−69 kJ/mol)

Other methods

Another method is the less well-known metabisulfite method, in which metabisulfite is placed at the bottom of a beaker, and 12.6 molar concentration hydrochloric acid is added. The resulting gas is bubbled through nitric acid, which will release brown/red vapors. The completion of the reaction is indicated by the ceasing of the fumes. This method does not produce an inseparable mist, which is quite convenient.

Sulfuric acid can be produced in the laboratory by burning sulfur in air and dissolving the gas produced in a hydrogen peroxide solution.

- SO2 + H2O2 → H2SO4

Prior to 1900, most sulfuric acid was manufactured by the lead chamber process.As late as 1940, up to 50% of sulfuric acid manufactured in the United States was produced by chamber process plants.

In early to mid 19th century "vitriol" plants existed, among other places, in Prestonpans Scotland, Shropshire and the Lagan Valley in County Antrim Ireland where it was used as a bleach for linen. Early bleaching of linen was done using milk but this was a slow process and the use of vitriol sped up the bleaching process